+++ Around 25,000 visitors from 125 countries +++ Industry celebrates the trade fair’s relaunch after pandemic-related cancellations +++ Over 70 per cent of trade visitors travelled from outside Germany +++ Exhibitors praise high-quality contacts +++ Event’s results exceeded expectations +++

After more than four years, the EISENWARENMESSE – INTERNATIONAL HARDWARE FAIR

2022 has celebrated a successful comeback in Cologne. Around 1,400 exhibitors from

50 countries took advantage of the opportunity to present their products and

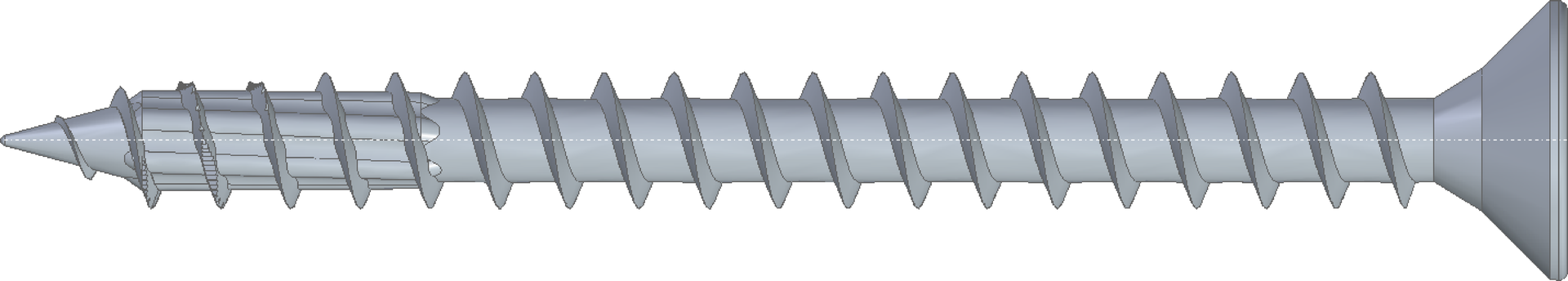

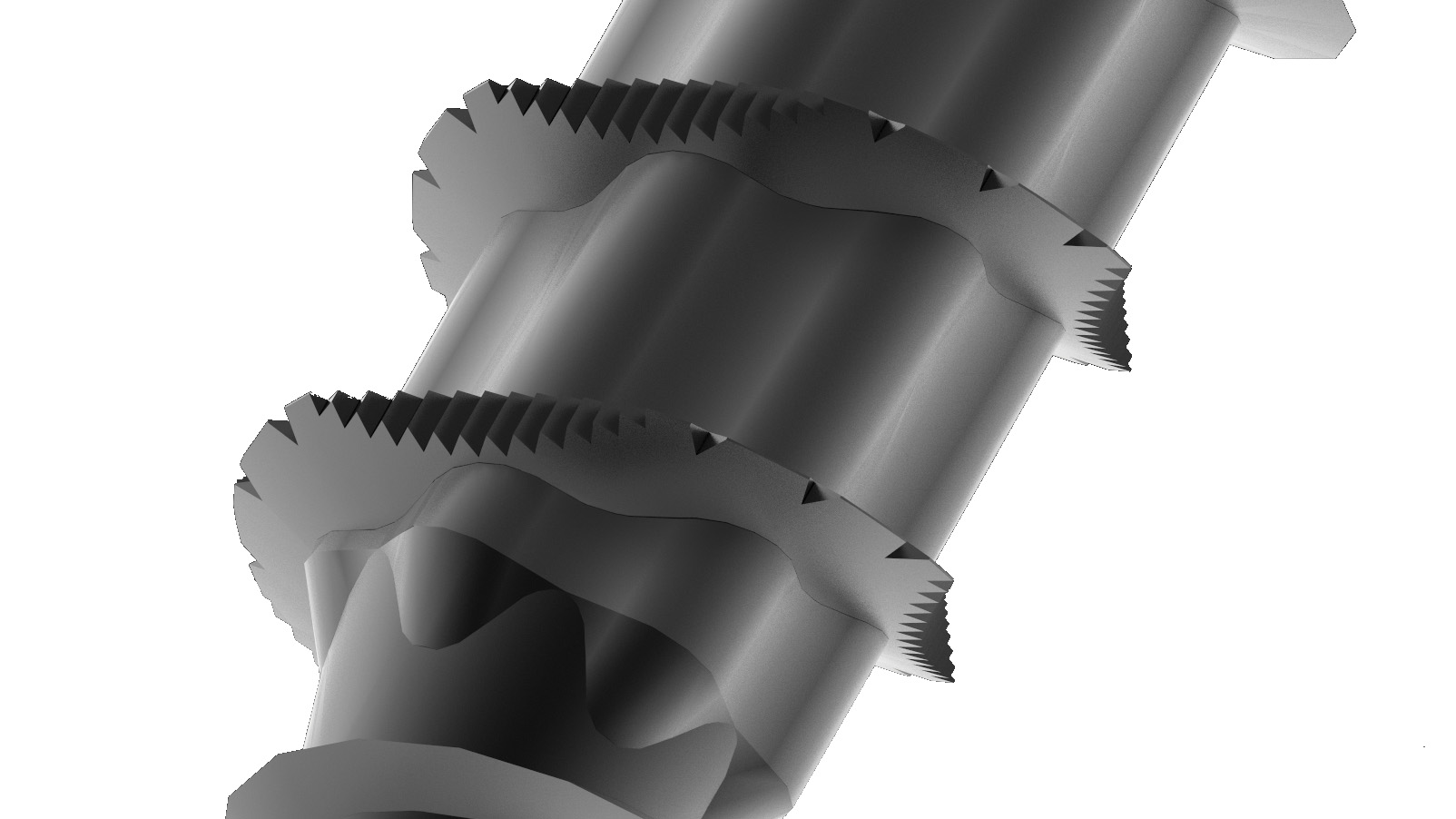

innovations to the entire hardware industry again. The spectrum of products

presented ranged from tools and accessories to building and DIY supplies all the way

through to fasteners, fixings and fittings.

After four successful days of trade fair activity, the EISENWARENMESSE –

INTERNATIONAL HARDWARE FAIR 2022 has closed its doors in Cologne. With around

25,000 trade visitors from 125 countries, the event returned after a 4.5-year

enforced break and immediately confirmed its importance as the number one trade

fair for the international hardware industry.

“The sense of relief at finally being able to meet face to face again after such a long

time and do business in person could be clearly felt among all our exhibitors and

trade visitors throughout the entire trade fair,” said Oliver Frese, Chief Operating

Officer of Koelnmesse GmbH. “You had the feeling that a big family was getting

together again after a long time apart.”

“The trade fair was a success, especially in the context of the ongoing travel

restrictions in Asia, the acute energy and raw materials crisis, and the geopolitical

situation in many countries. The feedback from our exhibitors about the business

contacts they’ve made is positive across the board. Clearly, companies made a

strategic decision to attend the EISENWARENMESSE – INTERNATIONAL HARDWARE

FAIR – the decision makers were here,” commented Oliver Frese.

EISEN Award 2022 powered by ZHH

The coveted EISEN Award was presented once again at the first EISENWARENMESSE –

INTERNATIONAL HARDWARE FAIR after the pandemic. This time, Koelnmesse

partnered with the German hardware trade association Zentralverband

Hartwarenhandel (ZHH). From the more than 50 innovative products submitted, the

expert jury selected the three prize winners of the EISEN Award 2022 powered by

ZHH. The prize winners include the AluTec hammer by Picard. The carpenter’s hammer

boasts a unique combination of aluminium and steel, which enables previously

unachievable ergonomics. The second winning entry is the Go! SMART measuring tool

by SOLA-Messwerkzeuge. At just 8 cm long, it brings the analogue and digital worlds

together and fulfils the functions of a spirit level, an inclinometer and a protractor.

Also among the EISEN Award winners for 2022 is ToughBuilt with its Scraper Utility

Knife – the world’s first two-in-one. The patented knife allows users to switch

between a utility knife and a scraper with the flick of a thumb.

DIY Boulevard 2022

In cooperation with the manufacturers’ association Haus & Garten, Koelnmesse

presented its 56 DIY suppliers with an exhibition area covering a total length of 272

metres, which had been fully booked long before the opening of the event. The DIY

Boulevard offered manufacturers the unique experience of being able to design the

POS in line with their branding with an authentic display of their merchandise as

well as the chance to make direct contact with end customers.

eCommerce area

The digital transformation does not stop at the hardware industry. The

EISENWARENMESSE – INTERNATIONAL HARDWARE FAIR has followed this development

closely. With the eCommerce area, it provided the ideal platform for both finding

and showcasing digital solutions. The spectrum of products and services ranged from

shop systems and electronic payment systems to data storage and processing all the

way through to search engine optimisation. The content of the eCommerce area was

curated by major names including eBay, OTTO, DHL, Facebook and Shopware.

What the industry’s saying about the EISENWARENMESSE – International Hardware

Fair 2022

John W. Herbert, General Secretary of the European DIY Retail Association

(EDRA) and the Global Home Improvement Network (GHIN)

“The EISENWARENMESSE – International Hardware Fair is the most important

platform for our industry. It’s both a barometer of trends and a trendsetter. In other

words, it’s the networking platform for the global hardware trade. I’m very happy to

be in Cologne, meeting so many colleagues from all over the world.”

Dr Peter Wüst, Managing Director of the German Retailers’ Association for Home

Improvement, Building and Gardening (BHB e.V.)

“I’m delighted to be at the EISENWARENMESSE – International Hardware Fair. The

event is absolutely vital for maintaining business relationships face-to-face in this

period of crisis. Despite the difficult times we find ourselves in, I’m picking up a

sense of optimism about the future from the people I’ve been talking to.”

Wolfgang J. Kirchhoff, Chairman of the Advisory Board of the

EISENWARENMESSE – International Hardware Fair

The EISENWARENMESSE – International Hardware Fair Cologne is still the industry’s

number-one event, where most of its innovations are presented. It’s the trade fair

with the strongest international profile, even though many visitors and exhibitors

from Asia have been unable to attend due to the pandemic.”

Dietrich Alberts, Managing Director of GAH-Alberts

“The EISENWARENMESSE – International Hardware Fair has earned its reputation as

the industry’s leading trade fair over many years. Exhibitors and visitors know they

can expect high quality across the board when they come here.”

Stefano Spillere, General Manager of Telwin SpA

“Telwin has been coming to the EISENWARENMESSE – International Hardware Fair for

more than 30 years. For us, the trade fair is very important in terms of cultivating

our network and maintaining contact with our international customers.

Paul Samms, Director of Licensing at Stanley Black & Decker, Inc.

“We’re over the moon to be back at the EISENWARENMESSE – International Hardware

Fair after a break of more than four years. Our international customers have told us

that they travelled to Cologne for the trade fair especially because of us. The

EISENWARENMESSE – International Hardware Fair is the ideal place to tap into new

areas of the market and find new retailers.”

Ferdinand Munk, owner and Managing Director of MUNK Group

“Of course, after the coronavirus pandemic, it’s great for the industry to get

together again at the EISENWARENMESSE – International Hardware Fair. The number

of contacts may not be as high as it used to be yet, but the quality is exceptional

because the visitors are enthusiastic about returning to Cologne to maintain their

business relationships in person.”

Thomas Dammann, Managing Director of the Central Association of the Hardware

Trade in Germany (ZHH e.V.)

“The EISENWARENMESSE – International Hardware Fair is particularly important for

the specialised trade because it provides the opportunity to maintain relationships

with international contacts and establish new ones. The trade fair is a chance to get

an overview of all the innovations and to be inspired by the other manufacturers.”

Sven Wilde, Head of Marketing Communications at Wiha Werkzeuge GmbH

“The EISENWARENMESSE – International Hardware Fair is the ideal opportunity for us

to meet our international customers and show them our products and solutions.

We’re very satisfied – even though the number of visitors to our stand was lower this

year, we feel that the quality of the discussions has been even higher than usual.”

Stefan Weigel, Executive Director/CMO at Wolfcraft

“At Wolfcraft, we don’t just focus on the product. Instead, we look at the bigger

picture in terms of sustainability and the customer journey as well as our products.

The EISENWARENMESSE – International Hardware Fair is a great opportunity for me to

explain this wide-ranging approach to visitors, so I’m very happy to be able to take

advantage of this platform. It’s a source of potential that we, as suppliers of

branded products, will continue to draw on in the future.”

The next EISENWARENMESSE – International Hardware Fair Cologne will be held

from 3 to 6 March 2024.

Koelnmesse – industry trade fairs for the hardware sector:

As a top international

trade fair organiser, Koelnmesse is the global market leader in organising events for

the hardware/ironware segment. It hosts the leading international event

EISENWARENMESSE – International Hardware Fair Cologne at its trade fair grounds in

Cologne, where Asia-Pacific Sourcing also showcases products, innovations and

trends for homes and gardens from the Far East. In addition to the events at its

Cologne headquarters, Koelnmesse is expanding its portfolio internationally in key

markets: The China International Hardware Show in Shanghai, the International

Hardware Fair Italy in Bergamo and the International Hardware Fair India in New

Delhi are bespoke events and leading trade fairs for the region with international

participation. They create the foundation for sustainable, international business for

their participants and bring together supply and demand within the sector with a

carefully targeted approach.

Further information: https://www.eisenwarenmesse.com/trade-fair/industry-tradefairs/

Author: Judith Leyendecker

Communications Manager

Koelnmesse GmbH

John W. Herbert, EDRA/GHIN General Secretary, shared his thoughts on the partnership, saying – “I am very much looking forward to my visit to Bergamo and to the first edition of International Hardware Fair Italy. That this is being organized by the Koelnmesse is for me a guarantee that this trade fair will be most professional and of interest to our international membership”

John W. Herbert, EDRA/GHIN General Secretary, shared his thoughts on the partnership, saying – “I am very much looking forward to my visit to Bergamo and to the first edition of International Hardware Fair Italy. That this is being organized by the Koelnmesse is for me a guarantee that this trade fair will be most professional and of interest to our international membership”  Thomas Rosolia, CEO of Koelnmesse Italy, commented “Thanks to the support of EDRA/GHIN we will continue to pursue our goal of establishing International Hardware Fair Italy as the most representative platform for the European hardware, DIY, garden & outdoor and building sectors in Italy.”

Thomas Rosolia, CEO of Koelnmesse Italy, commented “Thanks to the support of EDRA/GHIN we will continue to pursue our goal of establishing International Hardware Fair Italy as the most representative platform for the European hardware, DIY, garden & outdoor and building sectors in Italy.”

WISAR relies on the scale system iSCALE of Würth Industrie Service for reporting and reordering the requirements of production materials and other small parts based on weight.

WISAR relies on the scale system iSCALE of Würth Industrie Service for reporting and reordering the requirements of production materials and other small parts based on weight. Innovative scale system iSCALE of Würth Industrie Service for digital storage management.

Innovative scale system iSCALE of Würth Industrie Service for digital storage management.