It has been more than a year since COVID-19 pandemic has hit the world. All sectors have been experiencing tremendous impacts and pressures. Now, Indonesia's economy has turned positive and many sectors ready to bounce back.

Indonesia is one of the largest markets for motorized two-wheelers in the world. According to the study Global Industrial Fasteners, the OEM motor vehicle market is the largest outlet for industrial fasteners in Indonesia. Demand for industrial fasteners in Indonesia is projected to increase 7.3% per year to $1.1 billion in 2023, the second fastest among major national markets worldwide behind only India.

Besides that, Indonesia's manufacturing industry contributed of Indonesia Gross Domestic Product (GDP) grew 7.07% in the 2nd Quarter compared with a year earlier. Indonesia's automotive industry has remained one of the manufacturing sub-sectors contributing positively to the national industry.

Nowadays, Indonesia is still conducting massive in infrastructure development and it becomes one of positive effect to driving force for fastener market hence, global industrial fastener market will grow steadily.

Indonesia : The Update for COVID-19 and Vaccination

The COVID-19 pandemic in Indonesia is experiencing an improving trend, where positivity rate tests continue to decline. Over the past week, Indonesia's coronavirus positivity rate has fallen below the WHO (World Health Organization)'s benchmark standard of 5% for the first time, an indicator that the country's devastating second wave could be easing.

According to the government, the massive vaccination and PPKM (Community Activities Restrictions Enforcement) are factors to decrease the positivity rate in Indonesia. To this day Indonesia is ranked 6th in the world with the highest cumulative Covid-19 vaccination in the world. The vaccination in Jakarta has reached over 100% for the first dose and above 70% for the second dose.

INAFASTENER 2022 – The Exclusive Trade Show for Fastener & Fixing Industries

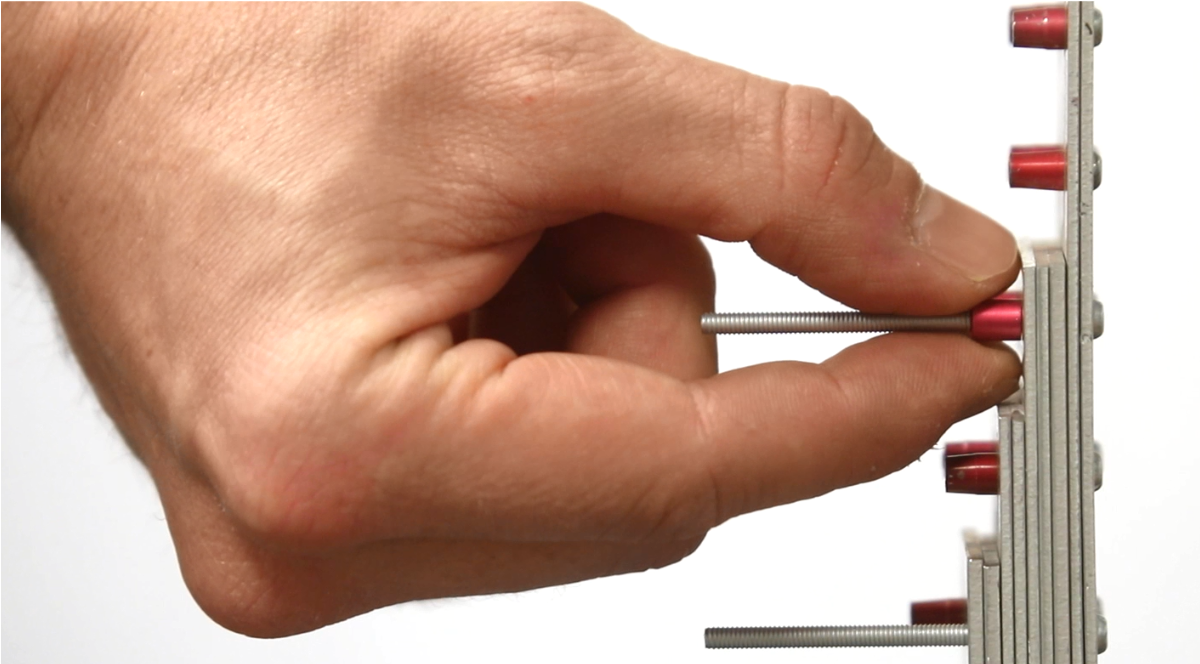

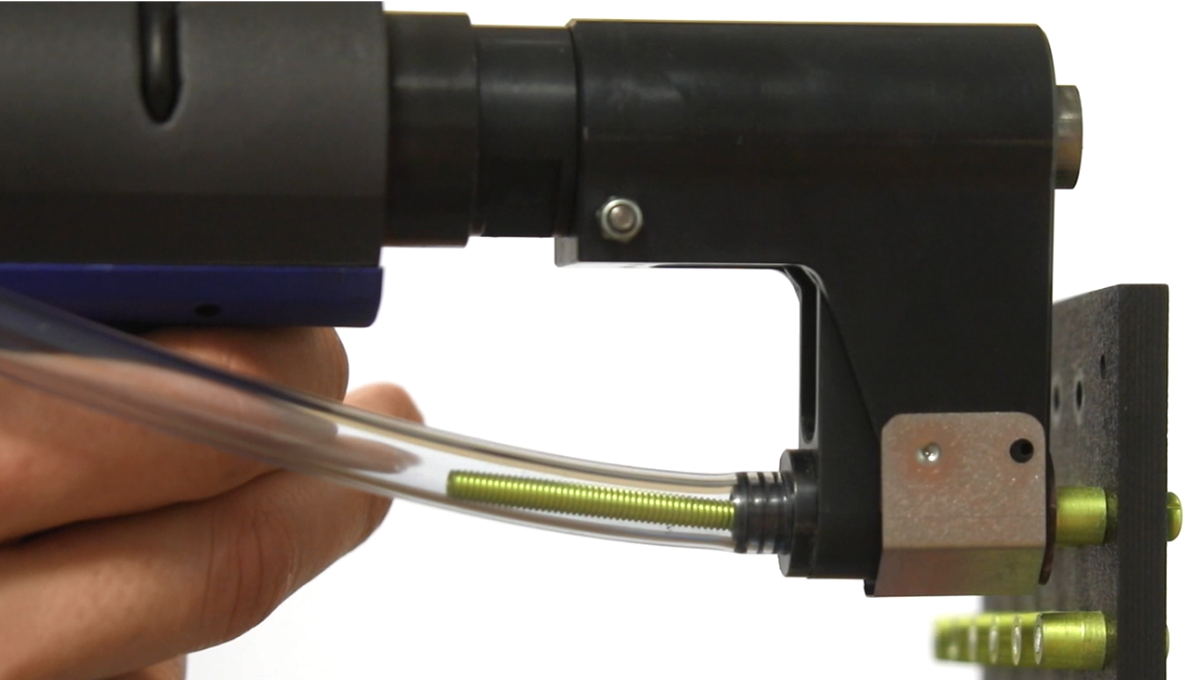

Fasteners become the most important part in the automotive industry and GEM Indonesia will hold INAFASTENER 2022 on March 23 – 25, 2022 at Jakarta International Expo (JIExpo) Kemayoran, Jakarta – Indonesia. INAFASTENER is part of INAPA exhibition of targeted trade exhibition for the fastener and fixing industry. In the meantime, INAPA has been proved as ASEAN’s Largest & Most Influential Trade Show for Automotive Industries and become a professional choice for global auto part, accessories and automotive technologies suppliers to gather, meet and discuss with their business partners in Indonesia.

The 5th edition of INAFASTENER will be a perfect platform for the industry to explore latest trends on the market, new products, technology and solutions at the same time. The show will be held together with INAPA, INABIKE, CON-MINE and Busworld Southeast Asia 2022. It will be the perfect opportunity where buyers and sellers having closer contact to reach a higher level of business.

Secure your participation now! For more information please contact : +62 21 54358118

or drop us an email : info@gem-indonesia.com

Author: Inafastener