Swiss ship builder Scheurer Bootswerft AG has opted for screws from Swedish specialist fastener maker BUMAX to fix its high-performance catamaran rudders where standard fasteners would simply fail.

High-strength BUMAX 109 screws are being used to fasten the A-Cat catamaran rudders constructed by Scheurer Bootswerft. An A-Cat catamaran has two rudders, and each Scheurer Bootswerft rudder is secured with two BUMAX 109 screws.

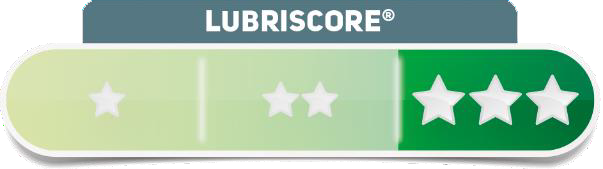

BUMAX 109 fasteners have a high molybdenum content which, coupled with unique BUMAX manufacturing processes and sourcing of the highest quality European raw material, makes it the strongest A4 fastener on the market. It offers high corrosion resistance and strength in demanding applications.

The BUMAX 109 is used for water jets, sub-sea equipment, pumps, valves, wind turbines, high-pressure equipment, nuclear plants, submarines, particle accelerators and many other applications where commodity A4 fasteners are inadequate. They provide greater safety and will last significantly longer than standard fasteners. “We originally used standard stainless steel A4 screws to fasten the rudders, but as the rudders come under very high tension when turning through the water at speed, we found that these screws were bending and eventually breaking,” said Aron Steinmann, CEO at Scheurer Bootswerft. “Even a small bend in these fasteners can alter the angle of the rudder, which reduces performance. Importantly, the high-strength BUMAX screws can cope with this high tension to keep the rudder at the correct angle while maintaining corrosion resistance in saltwater environments.”

Scheurer Bootswerft has also found that BUMAX fasteners can cope with sudden impacts, for example when the rudder hits debris in the water.

“The screws fastening the rudder are a simple but essential part of the catamaran as their failure can be the difference between winning or losing a race,” said Steinmann. “They simply cannot be allowed to fail.”

BUMAX is a Swedish manufacturer of premium stainless steel fasteners located in the Swedish “steel belt”. BUMAX is known as the strongest stainless steel bolt in the world – providing optimal safety and reliability to fasteners in the most demanding of applications.

Scheurer Bootswerft AG is a specialist ship builder based in Nidau, northwest Switzerland. The company has built A-Cat catamaran for regatta around the world for around 40 years. The A-Cat sailing class, often abbreviated to A-Cat, is a development class sailing catamaran for singlehanded racing.

Links:

Author: Nimeka Da Silva BUMAX Development Manager - UK & IRL