One-time postponement to the fall will ensure maximum participation from exhibitors and visitors including vital Asian sales and manufacturing markets

“As the world’s leading trade fair for the hardware industry, our aim is to provide a comprehensive overview of the global market and bring together suppliers and buyers from all over the world. With this in mind, we together with the associations and exhibitors have decided to hold the EISENWARENMESSE – INTERNATIONAL HARDWARE FAIR COLOGNE from 25 to 28 September 2022, instead of the originally scheduled dates of 6 to 9 March 2022,” announced Chief Operating Officer of Koelnmesse, Oliver Frese, in Cologne today.

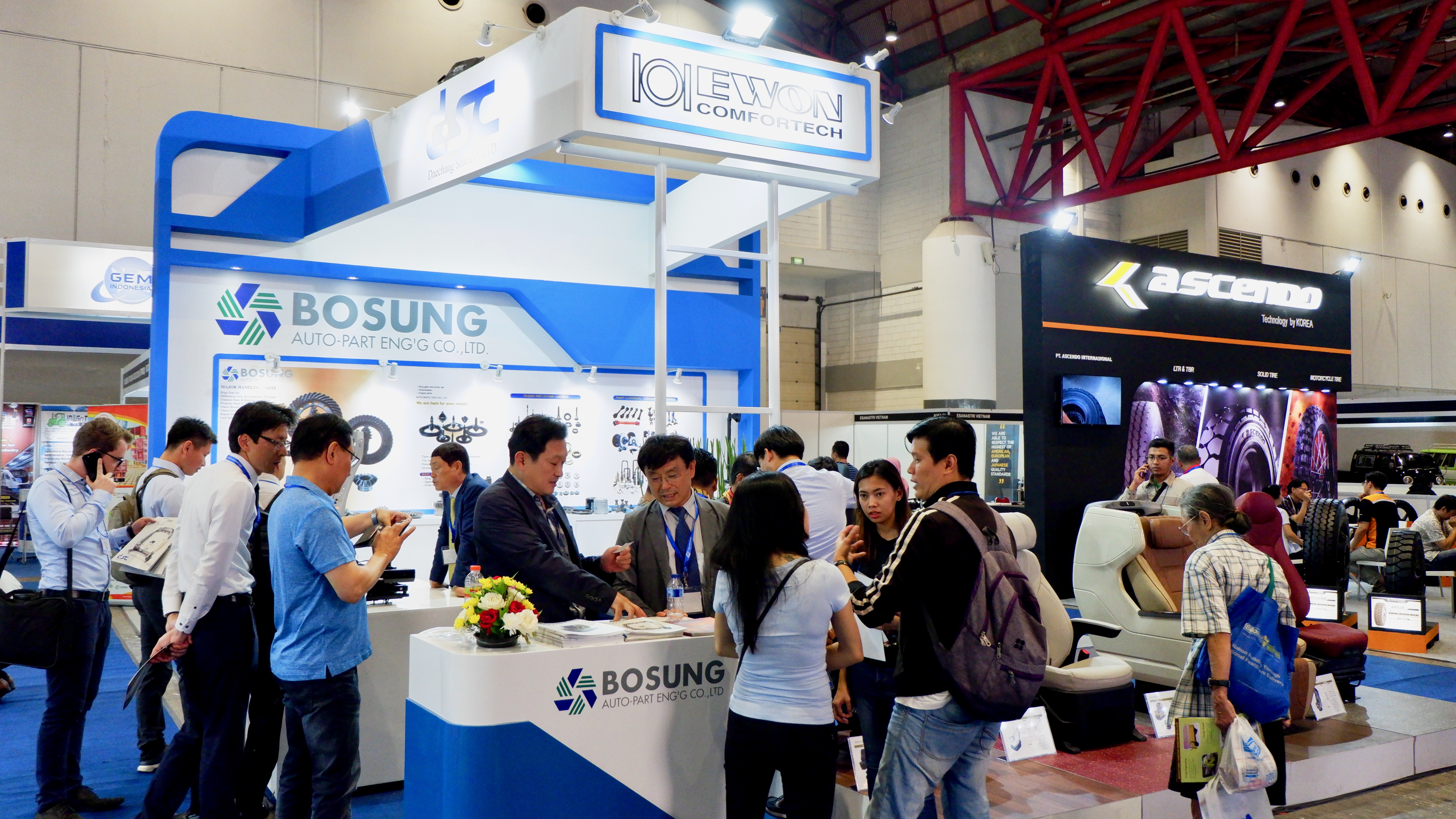

Since the pandemic situation continues to develop dynamically worldwide and strict travel restrictions are expected in March, especially for important Asian overseas markets, this scenario is a win-win for everyone: Exhibitors can plan for September with a longer lead time and look forward to the usual international audience, including from Asia. Visitors can look forward to a renowned group of participants and an attractive event programme shaped by a high number of exhibiting companies.

“With the Anuga Food Fair and International Dental Show (IDS) in the fall, we proved that trade fairs with Koelnmesse’s hygiene and safety concept are once again possible at an international level and can be carried out safely for everyone. Furthermore, our customers were very pleased with the business activities at these events,” pointed out Oliver Frese. “However, certain industry-specific conditions must be in place in order to fully leverage the power of personal exchange at an international trade show. In the case of EISENWARENMESSE – INTERNATIONAL HARDWARE FAIR COLOGNE, this power will be significantly greater in September thanks to the participation of the Asian market.”

The Asian manufacturing and sales market plays an important role in the hardware industry. Many Asian countries have again identified Germany and large parts of Europe as a risk area due to the generally high incidence figures, and travelling from these countries will be difficult well until spring. Based on the experience from 2021 and as the global vaccination campaign progresses, the situation should look completely different in September 2022.

The decision to postpone the EISENWARENMESSE – INTERNATIONAL HARDWARE FAIR COLOGNE was therefore made independently of the situation of other spring trade fairs in Koelnmesse’s portfolio, which have considerably different exhibitor and visitor structures in some cases.

Full support from the industry

“The industry needs a strong EISENWARENMESSE – INTERNATIONAL HARDWARE FAIR to build long-term success,” commented Wolfgang J. Kirchhoff, Chairman of the Advisory Board and Managing Director of Witte Tools. “If the conditions for this are better in September than in March, then postponing the date is the only logical and correct decision for the industry and the trade fair.”

"The German tool industry is strongly export-oriented. We therefore need an internationally widely attended INTERNATIONAL HARDWARE FAIR and we are confident that we will achieve this goal with the postponement,” said Managing Director of the German association of tool manufacturers (FWI) Stefan Horst regarding the postponement.

"First things first: we can continue to look forward to an INTERNATIONAL HARDWARE FAIR in 2022 and thus to an important instrument to prepare for the future in these turbulent times together as an industry. The postponement will enable all exhibiting companies to devote their full attention to the preparations for the fair after what is expected to be a hard winter," said Norbert Lindemann, Managing Director of Herstellerverband Haus & Garten e.V. (German Association of Home & Garden Manufacturers).

“Trade fairs are the lifeline of our international business activities and play an immense role in helping the pandemic-battered global economy get back on its feet. The EISENWARENMESSE – INTERNATIONAL HARDWARE FAIR is one of the events that we always recommend our members attend. The fact that we will have to wait to see each other in Cologne again in no way diminishes the anticipation,” says John Herbert, General Secretary of the European DIY Retail Association/Global Home Improvement Network (EDRA/GHIN) on behalf of the international DIY markets.

March event is not a blueprint

Planned for a long time and ready to go – top-class informative special exhibitions and theme platforms such as the eCommerce area featuring innovative, disruptive solutions and strategies for retailers in the areas of payment, shop systems, ERP, hosting, search engine optimisation and multichannel. The digital extension EISENWARENMESSE @home will be available in September also. “Nevertheless, we do not want to just take the plans for March and use them for September: The world simply changes too quickly,” said Matthias Becker, Director of EISENWARENMESSE – INTERNATIONAL HARDWARE FAIR COLOGNE. “We will look at the current hot topics in the industry and adapt the plans accordingly.”

Koelnmesse – industry trade fairs for the hardware sector: As a top international trade fair organiser, Koelnmesse is the global market leader in organising events for the hardware/ironware segment. It hosts the leading international event EISENWARENMESSE – International Hardware Fair Cologne at its trade fair grounds in Cologne, where Asia-Pacific Sourcing also showcases products, innovations and trends for homes and gardens from the Far East. In addition to the events at its Cologne headquarters, Koelnmesse is expanding its portfolio internationally in key markets: China International Hardware Show (CIHS) in Shanghai and Hardware Forum Italy in Milan are bespoke events and leading regional trade fairs. They create the foundation for sustainable, international business for their participants and bring together supply and demand within the sector with a carefully targeted approach.

Further information: https://www.eisenwarenmesse.com/trade-fair/industry-trade-fairs/

The next events:

Hardware Forum Italy - The hardware expo and forum, Milano September 2022

China International Hardware Show - Leading Trade Fair for Tools, DIY and Building Hardware, Fasteners, Security Systems, Locks and Fittings, Shanghai 21.09. - 23.09.2022

For more information please follow EISENWARENMESSE – INTERNATIONAL HARDWARE FAIR

On Facebook:

www.facebook.com/eisenwarenmesse

On Twitter:

www.twitter.com/eisenwarenmesse

On LinkedIN

www.linkedin.com/showcase/eisenwarenmesse

Author: Judith Leyendecker Communications Manager

The 9th Fastener Fair Global, International Exhibition for the Fastener and Fixing Industry, ended last week after three successful show days at the Messe Stuttgart exhibition centre in Germany. Almost 11,000 trade visitors from 83 countries attended the event to discover the latest innovations, products, and services from all areas of fastener and fixing technology and to connect with other industry professionals from various manufacturing and industrial sectors.

The 9th Fastener Fair Global, International Exhibition for the Fastener and Fixing Industry, ended last week after three successful show days at the Messe Stuttgart exhibition centre in Germany. Almost 11,000 trade visitors from 83 countries attended the event to discover the latest innovations, products, and services from all areas of fastener and fixing technology and to connect with other industry professionals from various manufacturing and industrial sectors.