Goebel GmbH announces a new and exciting partnership with Tower Fasteners EU Ltd as an official authorized distributor for all products & tooling.

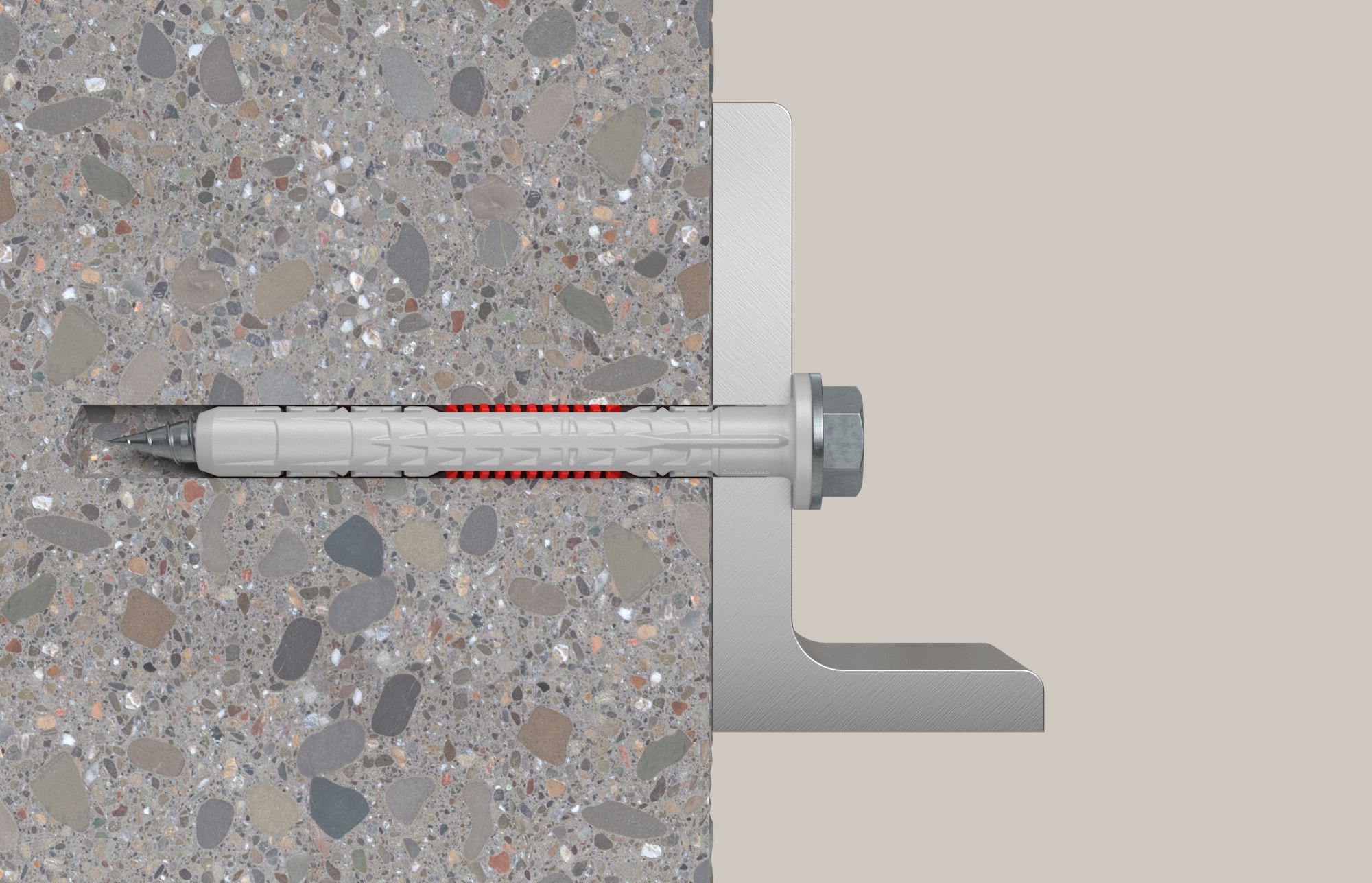

The two companies entered into an agreement that sees Tower Fasteners EU Ltd become an authorized distributor for Goebel GmbH product lines which consist of: Blind Rivets, Threaded Inserts, new G-Grip™ Stainless Lockbolt System, Self-Tapping/Drilling Screws, Sealing Washers, Drill Bits, Nut Drivers, Over-Center Toggle Latches, Hand & Power Tools, PPE Equipment, and many more innovative specialty products.

“Goebel GmbH is pleased to partner with Tower Fasteners EU Ltd to distribute our blind fastening product lines, over-center latches, new G-Grip™ Stainless Lockbolt System, and other product lines throughout the Republic of Ireland. For over 50 years Tower Fasteners has been a leader in the field of fastener distribution and “C” class commodity inventory management systems. Their persistence about making sure it’s the right part, on time, every time supports their commitment to supply products from only the highest quality manufacturers; it is an integral part of their longevity and success in this business. Tower Fasteners EU Ltd is a great fit for our company’s vision and we are looking forward to working together for years to come.”, said Marcel Goebel, CEO of the Goebel Group.

Derry Cronin, Key Account Manager was equally pleased stating. “From the very first day into the present time, Tower Fasteners continues to set the standard for innovation and excellence in fastener distribution. Tower Fasteners is committed to providing world class products and services the first time and every time. Each and every Tower employee shares the Shannon family's commitment to total customer satisfaction. Partnering with Goebel GmbH and distributing their innovative fastener solutions will help us provide our customers new products that will help streamline their manufacturing processes. Tower Fastener employees go above and beyond to help customers find solutions to their problems.”

About Tower Fasteners

Thomas J. Shannon founded Tower Fasteners in 1967 in Mineola, New York. Mr. Shannon's philosophy was a simple but powerful one: provide his customers with the products they needed, when they needed them, without fail. Because of Mr. Shannon's strong commitment to customer satisfaction, Tower Fasteners continued to grow year by year.

The company relocated several times to larger facilities across Long Island. The first Tower distribution center, in Fort Lauderdale, Florida, which is now a sales office, was opened in 1975. In 1986, Tower designed and built its current corporate headquarters, in Holtsville, New York. Additional distribution centers in New England, Pennsylvania, New Jersey, North Carolina, Mexico, and Texas are currently servicing Tower customers along the East Coast and Southwest of the United States, as well as in Mexico. In 2018, Tower Fasteners opened its first European distribution center in Dublin, Ireland. Tower Fasteners EU Ltd is located less than thirty minutes outside of Dublin’s city center and will serve as Tower’s European headquarters. Tower has grown from a one-person organization to a company that employs over 100 people in eight states. Today, Tower Fasteners is being managed by a second generation of Shannon's that have inherited Thomas J. Shannon's passion for, and commitment to, excellence. For more information visit https://www.towerfast.com/

About Goebel

The Goebel Group is a family-run and internationally active business group of joining and assembly technology. Considered specialists in the development of innovative and high-quality joining elements and corresponding processing systems, their friendly and experienced staff, representatives, and distribution partners take care that customers are satisfied and actively support the entire supply chain as well as value chain. For more information visit https://www.goebel-group.com

Author: Goebel