With less than a month before Fastener Fair Global opens its doors from 21-23 March 2023 at Messe Stuttgart in Germany, the exhibition is shaping up to be a record-breaking 9th edition. The show has grown since the last event in 2019: now covering a net exhibition space of over 23,000 sqm, a 1,000 sqm more compared to the previous event, Fastener Fair Global 2023 allocates an additional hall to the exhibition ground and occupies four halls for the first time ever. Thus, the exhibition reconfirms itself as an international marketplace for the fastener and fixing industry to find new business contacts, exchange expertise and build targeted business partnerships.

Taking place across halls 1, 3, 5 and 7, over 980 exhibitors have joined the event to showcase a comprehensive portfolio of fastener and fixings products, machines, equipment, tools and related services. Exhibiting companies come from 43 different countries, reconfirming the international reach of the event. Representing global firms, from SMEs to large multinational corporations, exhibitors mainly come from Germany, Italy, China, Taiwan, India, Turkey, the Netherlands, the UK, Spain and France. Exhibitors include: Albert Pasvahl (GmbH & Co.), Alexander P A A L GmbH, Ambrovit S.p.A., Böllhoff GmbH, CHAVESBAO, Eurobolt BV, F. REYHER Nchfg. GmbH & Co. KG, Fastbolt Schraubengroßhandels GmbH, INDEX Fixing Systems, INOXMARE SRL, Lederer GmbH, Norm Fasteners, Obel Civata San. ve Tic. A.S, SACMA LIMBIATE SPA, Schäfer + Peters GmbH, Tecfi Spa, WASI GmbH, Würth Industrie Service GmbH & Co. KG and many more.

Commenting on the event build-up, Nicola Hamann, Managing Director at RX, organiser of the event, states: "The strong exhibitor participation in Fastener Fair Global 2023 testifies to the importance of the event as a milestone for the Fastener and fixing sector internationally and serves as an economic indicator of the growth of this industry. Benefitting from high investment in the construction sector, rising demand for industrial fasteners in the automotive and aerospace industries and continued growth predictions at a steady rate from 2022 to 2030, Fastener Fair Global 2023 is well-placed to showcase the innovations of companies at the forefront of this fast-moving industry".

What's on at the show

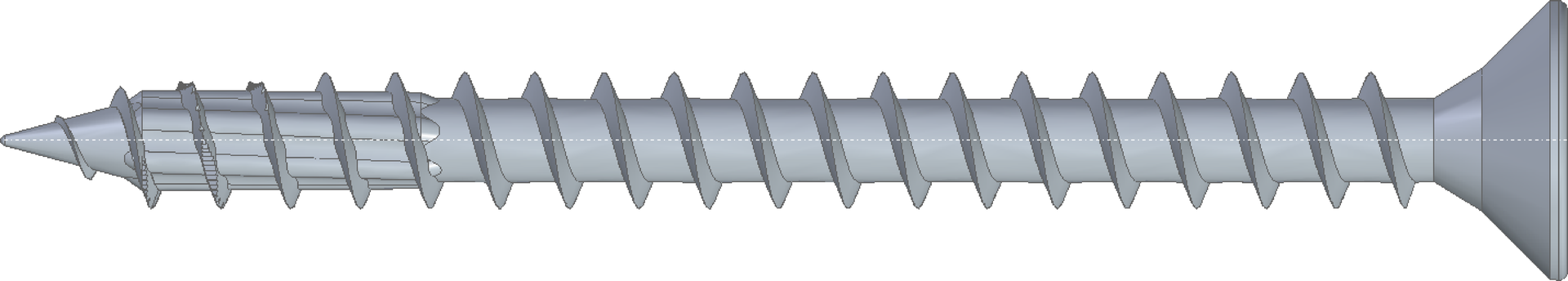

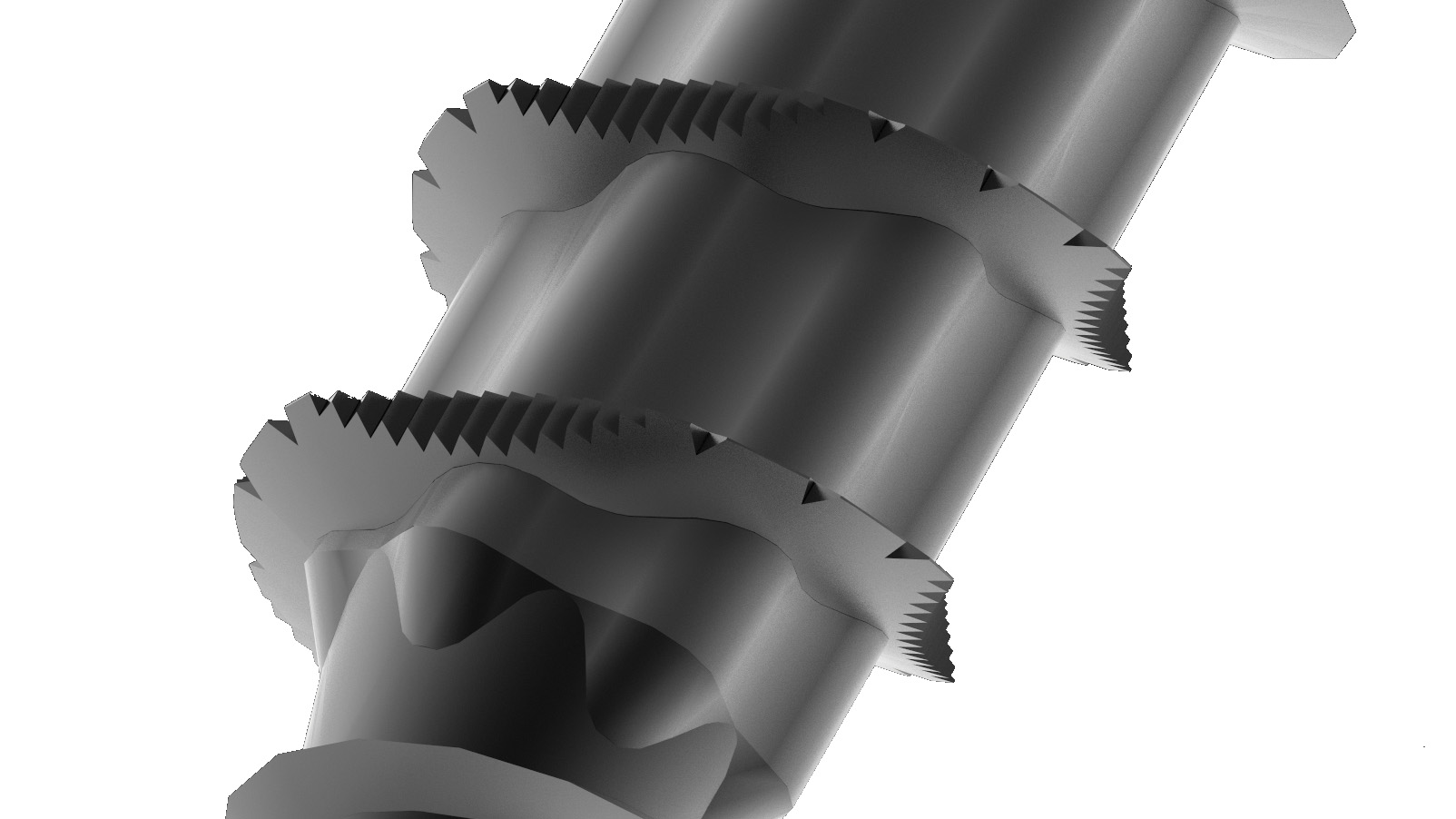

For manufacturers, wholesalers, distributors and suppliers, Fastener Fair Global is the ideal marketplace to source and trade products and solutions across all areas of fastener and fixing technology. Fastener Fair Global welcomes distributors, suppliers, engineers and other industry professionals from a broad range of industries, such as construction, automotive, transport, electronic and electrical goods, energy and power generation and many more.

To explore the wide variety of innovations, technologies and systems presented at the exhibition ahead of the event, attendees can access the Online Show Preview, which showcases the highlights of this year's event, and select in advance products and services they are interested in. The Online Show Preview is available here.

A first-hand opportunity to assess new products and services introduced by exhibitors to the market within the last 24 months will be through the Route to Fastener Innovation competition, organised by the media partner Fastener + Fixing Magazine. On the second day of the event at 2:00 pm, its editorial team will present the top three winners with the accolade of being Fastener Technology Innovators. The award will take place at the Fastener + Fixing Magazine stand, 3874, in hall 7.

Key Visitor Information

Visitors can purchase tickets online now at www.fastenerfairglobal.com at a discounted rate of €39 before the price increases to €55 for ticket purchases on-site. All entrance tickets are valid for all three show days.

International visitors requiring a visa for travel can download an invitation letter for visa application directly from the ticket purchase confirmation email.

The exhibition grounds in Stuttgart are easily accessed via car or public transport and are within walking distance of Stuttgart airport. The opening times are from 09:00 to 18:00 on Tuesday and Wednesday and from 09:00 to 16:00 on Thursday.

For more information on Fastener Fair Global 2023, visit https://www.fastenerfairglobal.com/

Fastener Fairs – connecting fastener professionals worldwide

Fastener Fair Global is organised by RX Global. It belongs to the highly successful worldwide series of Fastener Fair exhibitions for the fastener and fixings industry. Fastener Fair Global is the portfolio flagship event. The portfolio also contains regionally focused events such as Fastener Fair Italy, Fastener Fair India, Fastener Fair Mexico and Fastener Fair USA.

Author: Gloria Vezzoli PR & Marketing Manager

Author: Cameron Ross PR & Marketing Executive