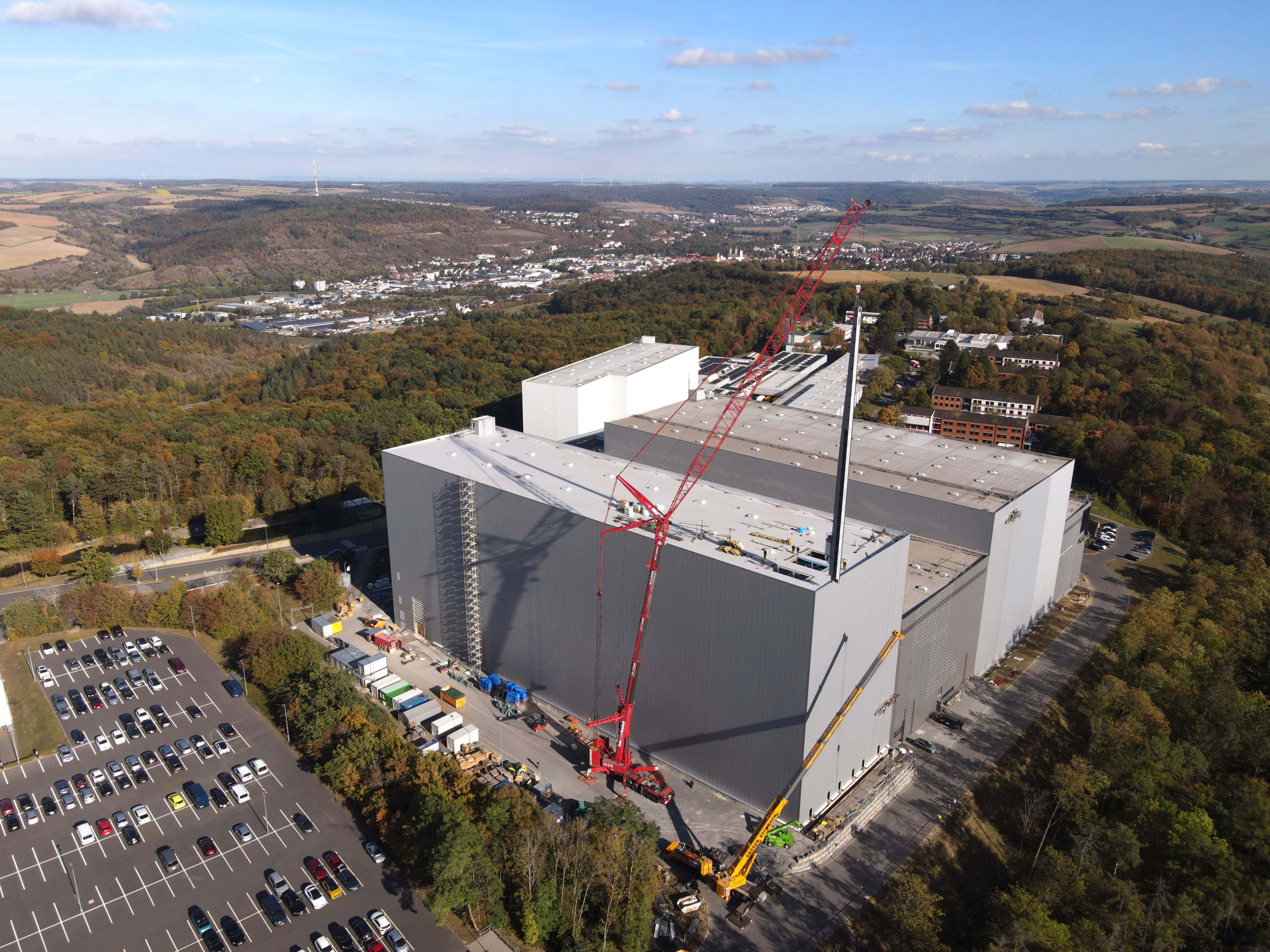

Bad Mergentheim/Main-Tauber-Kreis. 46 metres long, weighing 22,5 tonnes, manoeuvred 100 metres over the roofs: A true work requiring precision, weighing several tons on the heights of Drillberg. The excavations for building a new automated high-bay warehouse with additional 59,000 storage spaces covering more than 4,000 square metres started as early as July 2022. Last Monday, 16th October 2023, the first storage and retrieval machines were brought in to take over the automated storage and retrieval of pallets in the warehouse. Würth Industrie Service GmbH & Co. KG thus has its sights firmly set on commissioning in April 2024.

Würth Industrial Park is considered as one of the most advanced logistics centres for industrial supply in the entire Europe. With over 65,000 square metres, which is equivalent to about 9 football fields, it is the pulsating linchpin of the company. From here, around 20,000 customers are securely supplied with production resources as well as auxiliary and operating materials. Modern, fully automated high-bay and shuttle warehouses with a capacity of more than 650,000 storage locations, a 34-kilometre-long conveyor system, autonomous bin shuttles, camera inspection systems and self-learning robots are used – all with the goal of ensuring optimised workplace ergonomics, a sustainably healthy way of working by taking over physically stressful tasks and an increased level of automation and digitalisation. In order to ensure the long-term supply security for all customers across Europe and to meet the demands of an increasingly growing product range of currently 1.4 million items, Würth Industrie Service is consistently investing in further expanding its warehouse capacity. With the new high-bay warehouse – 50 metres high, 34 metres wide, 121 metres long - the provider of C-Parts management is once again expanding its capacities by 59,000 additional pallet storage spaces. This increases the high-bay capacity at the Bad Mergentheim location by about 33 percent to a total of 235,000 pallet storage spaces. Now that the silo-type shelving system has been completed, three of six storage and retrieval machines (SRM for short) have been brought in. Over an aisle length of 120 metres, the rail-guided vehicles will now take over the fully automated storage and retrieval of pallets with small parts in the warehouse. They will operate in six aisles with a maximum travel speed of 180 m/min and a lifting speed of up to 70 m/min. Each SRM has two telescopic forks as load handling attachments with a total load capacity of approximately 2,400 kg. The efficient 46 metre high storage and retrieval machines are particularly economical on space thanks to their single column design, and can carry out up to 600 pallet movements per hour with their two load handling attachments.

"With the new high-bay warehouse, we are realising dimensions that rarely exist in this overall complexity. The logistical expansion will thus significantly increase the efficiency and capacity in the entire value-added process.”, said Helmut Eisenkolb, Head of Logistics at Würth Industrie Service.

In Kardex, Würth Industrie Service has found a partner that is a true expert in its field as a globally active industrial partner for intralogistics solutions and as a leading provider of automated storage solutions and material flow systems. "In a project of this magnitude, it is always impressive to see so many experts with a wide range of expertise acting as one big unit in the shortest possible time," says Lars Wagner, Project Manager, Operations New Business Refurbishment at MLOG Logistics GmbH.

Millimetre by millimetre

In order to safely transport the storage and retrieval machines from Kardex’s production site in Neuenstadt am Kocher to Bad Mergentheim by heavy goods transport, a total of three 55-metre-long trucks were utilised to transport the systems to Drillberg. With the utmost precision, the crane operators steered the 22.5-tonne machines over the still open roof into the high-bay warehouse. At a height of 100 metres, it was a real precision work for all those responsible.

Sustainability in focus

With the construction measures being currently implemented and planned, Würth Industrie Service is taking significant steps to ensure a seamless supply to the customers in the future as well as is contributing to consciously acting sustainably. How does this work in the case of the storage and retrieval machines? The energy requirement of the storage and retrieval machines is optimised by means of DC link coupling, which can divert the energy between two drives in a sensible manner. This means that the energy saved by the lift drive during lowering can in turn be used for the travel drive. In addition, the storage and retrieval machines from kardex are convincing in terms of robustness, durability, maintenance and, above all, quality. Another contribution to sustainability is the greenhouse gas-neutral energy supply. For this reason, the south facade of the new high-bay warehouse will be equipped with a large-scale photovoltaic system with a total output of 1,028 kWp. This is intended to achieve a total output of over 2,000 kWp and a generation volume of around 1,500,000 kWh at Würth Industrial Park. Always being one step ahead and acting sustainably and with foresight is what the company stands for.