Transformed supply chains and international cooperation networks, the war in Ukraine, an increase in production costs, the introduction of carbon tariffs (CBAM), competition with countries with low production costs, smooth adaptation to changing customer needs, investments in innovation and new technologies - these are the topics that manufacturers and distributors will discuss during the FASTENER POLAND® International Trade Fair of Fastener and Fixing Technology. The 6th edition of the event will take place on October 18-19, 2023 at EXPO Krakow, and the theme will be ecology.

The entire industry in one place

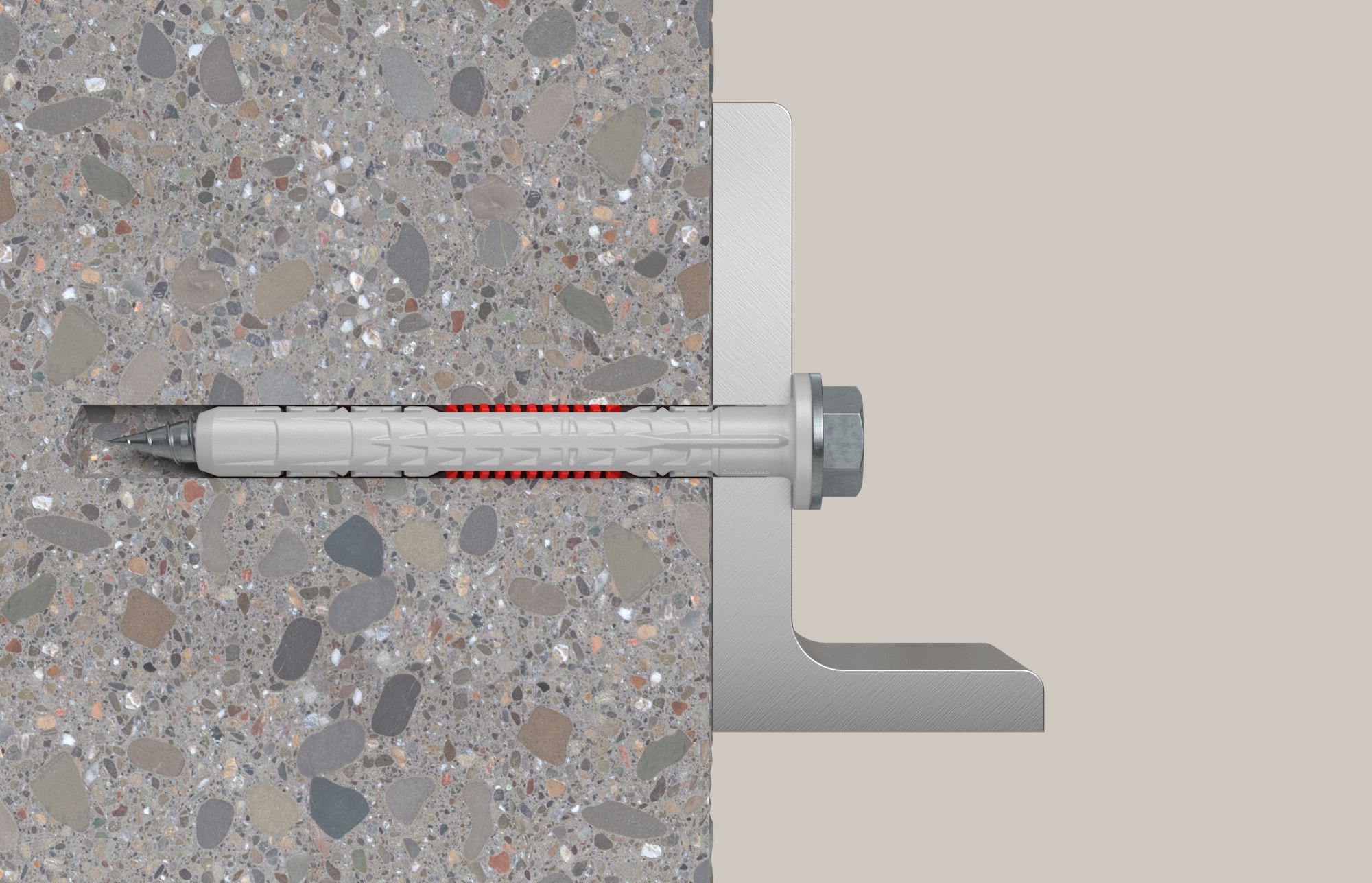

The FASTENER POLAND® is the only international fair of fasteners organized in Central and Eastern Europe - a key forum for exchanging experiences, learning about new products, as well as building effective trade relations between companies from around the world. The pandemic has shown very clearly that face-to-face meetings cannot be replaced in business. FASTENER POLAND® is back to its pre-pandemic state. In October, over 150 companies from 15 countries will present their offer. They will present the most modern industrial fasteners and fittings (from screws, through rivets to nuts, pins or wedges), construction fasteners (anchors, concrete screws, fixing facades and insulation), advanced assembly and installation systems (with the presentation of the latest riveting devices, screwdrivers and screw insertion systems or assembly brackets), as well as technologies for the production of fasteners and devices for their storage and distribution.

We connect buyers from all over the world

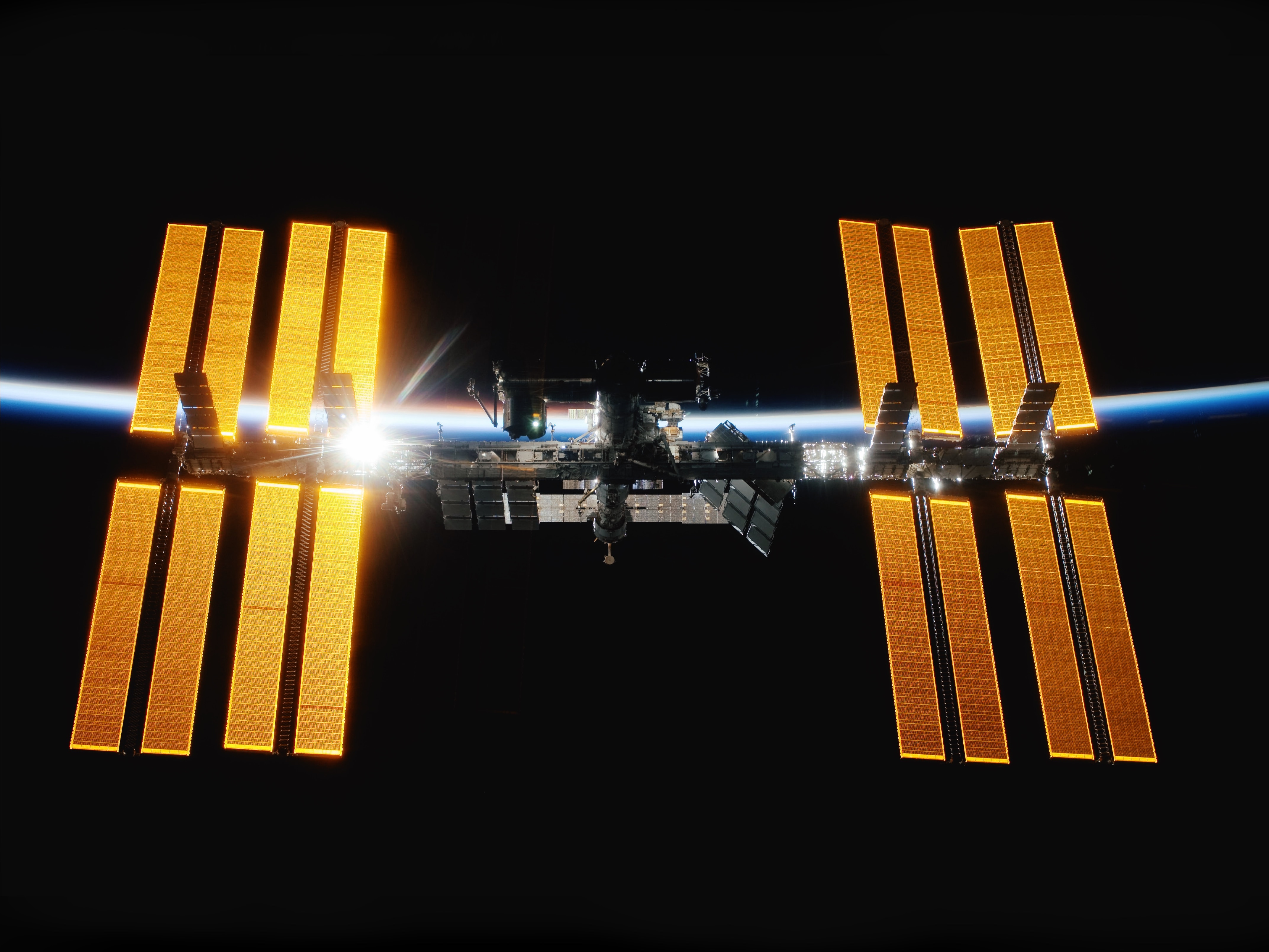

The fair will be visited by buyers from industries that use fasteners for the production of their products. This year, the organizers direct the promotional campaign especially to industries with the greatest potential. Photovoltaics, automotive, aviation and the medical industry are sectors with the greatest demand for all types of fasteners and fixings. Poland is among the top ten countries in the world in terms of the size of the photovoltaic market. In Europe, only Germany and Spain are ahead of us in this regard. The industry records continuous sales increases and is developing dynamically. Therefore, the demand for components is growing, in particular for specialized and quality fasteners. The fasteners market responds to these needs by designing and delivering the best solutions with enhanced resistance to difficult conditions in which solar systems are used. Several dozen manufacturers will present their solutions on a special zone dedicated to this industry.

Bleisure - combining business with spare time

We believe that success begins with meetings, therefore organizers encourage everyone interested in expanding business contacts to participate in the fair. In addition to free invitations to the fair, a program combining business travel with leisure was developed. Trend Bleisure - a word created from the combination of the words "business" and "leisure" - is the key message of the strategy implemented by Targi w Krakowie Ltd. Participants of the fair will be inspired by the map of attractions, which will include recommended accommodation, local restaurants, monuments, climatic places and cultural centers. And since there is no shortage of interesting places in Krakow, the organizers are sure that some customers will extend their stay by additional days.

List of exhibitors, trade fair novelties, free registration for guests, hotel offer and a list of recommended restaurants and places worth visiting at www.fastenerpoland.pl

Author: FASTENER POLAND®

Image 1

Image 1 Image 2

Image 2 Image 3

Image 3 Image 4

Image 4 Image 5

Image 5 Image 6

Image 6 Image 7

Image 7 Image 8

Image 8