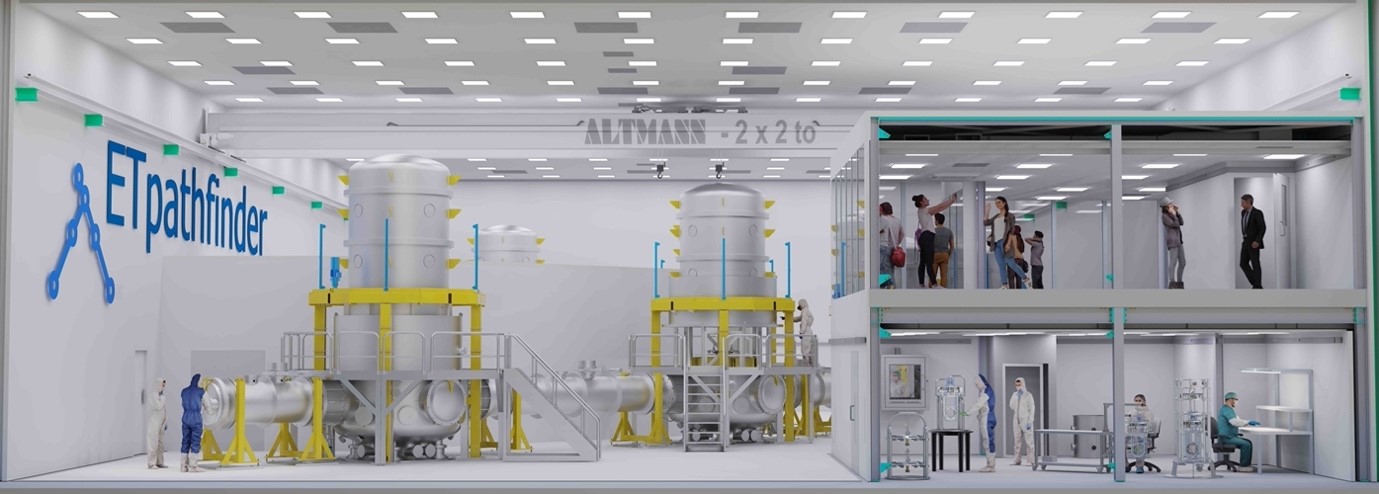

Swedish specialist fastener manufacturer BUMAX has been selected to supply premium fasteners to ETpathfinder, an R&D facility at Maastricht University for testing and prototyping innovative concepts and enabling new technologies for the Einstein Telescope (ET).

The Einstein Telescope is a next generation underground gravitational wave observatory. The ET is being developed to be 100 times more sensitive than current instruments and is scheduled for completion in 2035. The telescope will enable scientists to study the precise structure of neutron stars, the birth of black holes and the structure of the universe immediately after the Big Bang.

Regular fasteners not an option

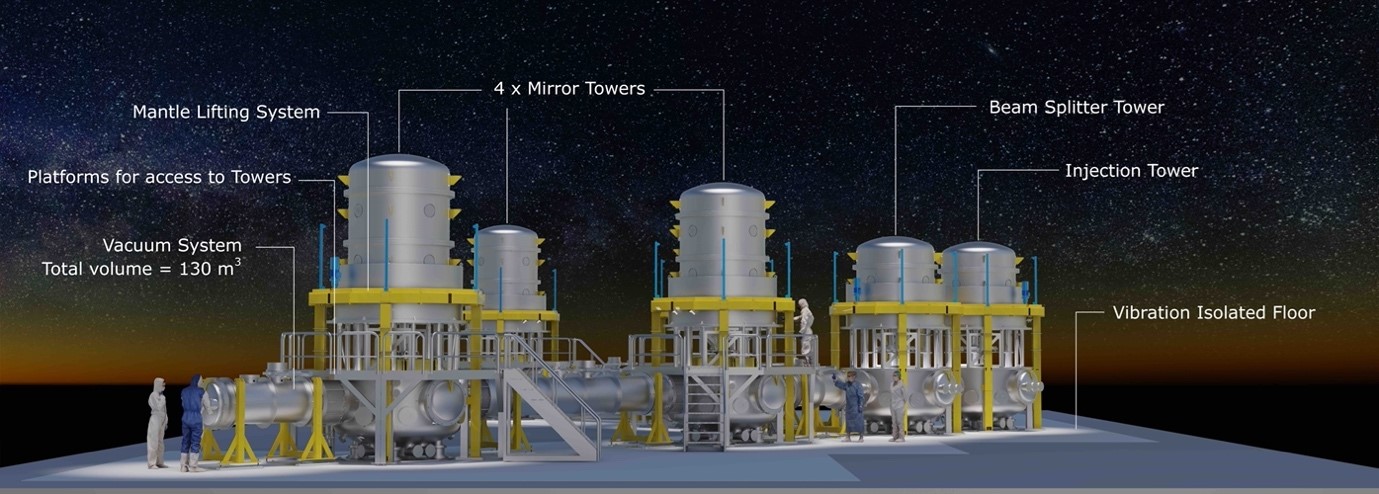

The ETpathfinder equipment is currently being assembled in a cleanroom that includes a large vacuum vessel containing various optics and seismic attenuation structures to isolate the test setup as much as possible from any noise from the outside world. The test setup resides in a vacuum to further remove vibrations carried through the air, and to also minimize interference of air molecules with the optics and lasers.

“Because we can’t use any oils or lubricants in our cleanroom, regular fasteners just aren’t an option,” explains Mathijs Baars, Mechanical Engineer at the Dutch National Institute for Subatomic Physics (Nikhef). “We investigated various fastener alternatives, including titanium-nitride coated fasteners, but BUMAX was the only solution that fully met our requirements while still being cost effective.”

Anti-galling properties crucial

BUMAX is supplying bolts, washers and nuts in the BUMAX 88 stainless steel grade which offers anti-galling properties. Galling is common with regular stainless steel fasteners and involves the fastener seizing up with the internal threads as a result of cold welding. In the ETpathfinder project, some parts may need to be disassembled and reassembled more than 100 times over the coming couple of decades. Any galling issues would have serious consequences for the project.

“The worst-case scenario for us would be if a galled fastener were to weld with one of our custom-made vacuum parts as these would be very costly to replace,” says Baars. “This is why choosing fasteners with anti-galling properties is essential risk management for the entire ETpathfinder project – particularly in the vacuum chamber where we will only use BUMAX fasteners.”

The BUMAX® 88 bolts and nuts delivered to the ETpathfinder project are electro polished, receive kolsterised treatment and are cleanroom packed. This is important to avoid particles from the nuts and bolts in the ETpathfinder cleanroom and Kolsterisation increases surface hardness, which further reduces the risk of galling.

Cryogenic temperature resistance

The ETpathfinder mirrors will be cooled to 8K (-265°C) when they are operational to ensure optimum performance. The mirrors are cooled to reduce thermal noise, which is the vibration of atoms that scales with that atom’s temperature.

Metals typically become brittle at cryogenic temperatures, which makes them prone to sudden failure. However, BUMAX® 88 fasteners provide good resistance to cryogenic temperatures due to their high material quality, low impurities and high-quality finish. Third-party tests have shown that BUMAX® 88 fasteners retain excellent ductility even in temperatures as low as 0K (-273°C).

BUMAX often chosen for challenging scientific R&D projects and other hi-tech manufacturing industries

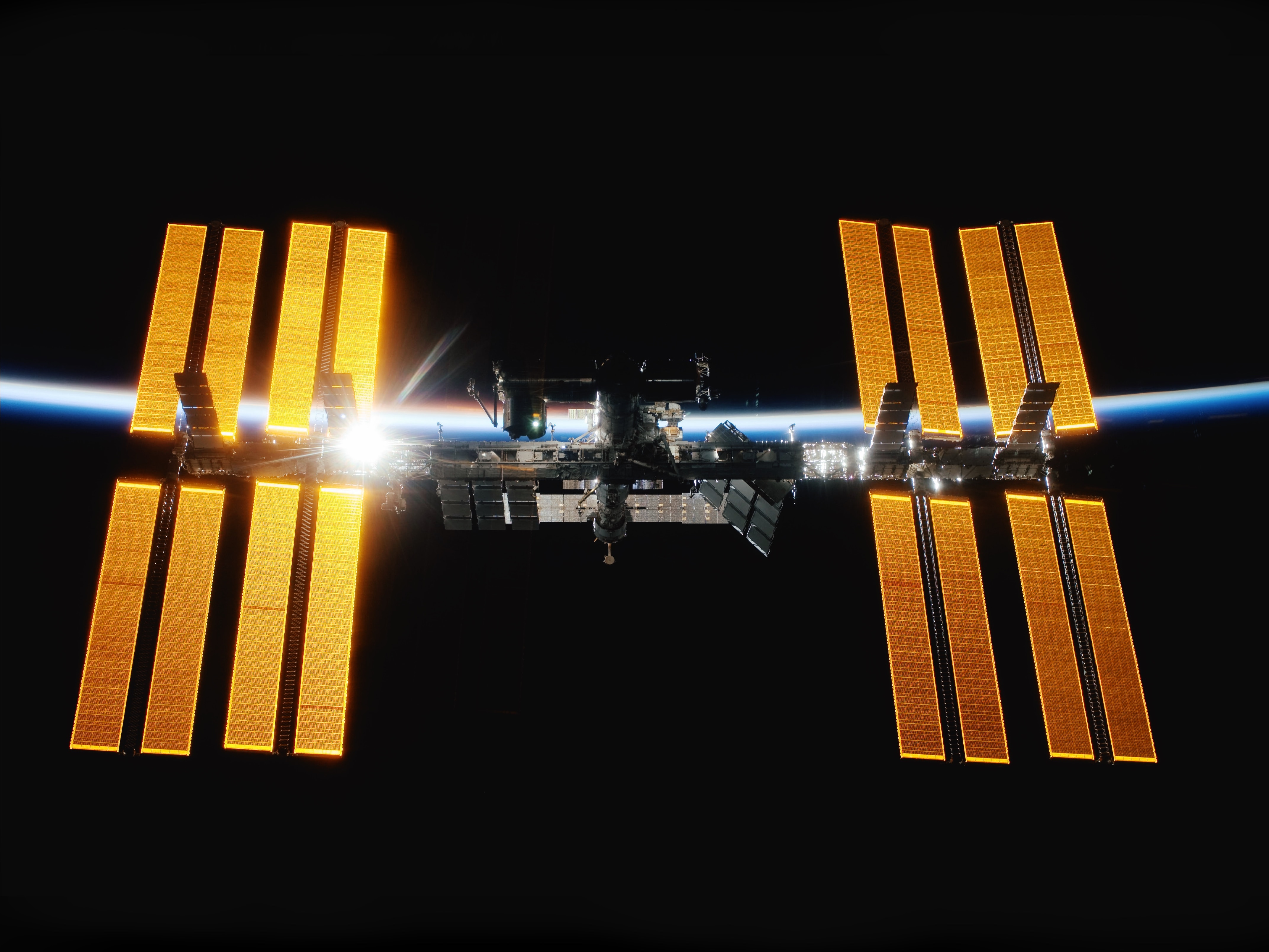

“Our premium fasteners have been chosen for many scientific high-profile projects and products, including CERN and ISS , and this is yet another one,” said Lars Holm, Managing Director of BUMAX. “We are very proud to have been selected to be part of the Einstein Telescope project, which is of course testament to the high quality of our products.”

Author: BUMAX