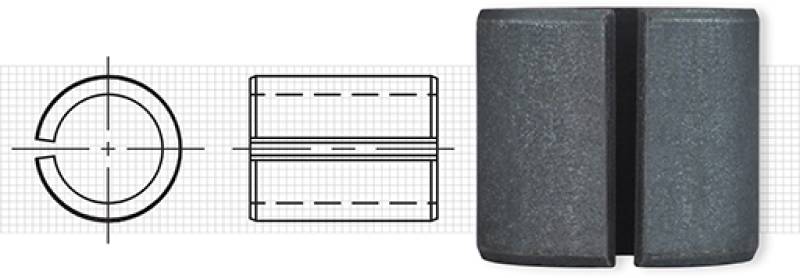

SPIROL is pleased to introduce the new CL220 Split Seam – Extra Clearance Compression Limiter to their expansive product offering. This post-mold installed Compression Limiter has a flexible diameter to accommodate wide hole tolerances, while the seam is designed to prevent interlocking in the free state. The spring force generated during installation provides self-retention of the Limiter within the plastic assembly. Once installed, the CL220 provides a minimum clearance of 1mm over the bolt diameter; 0.5mm greater clearance than that provided by SPIROL’s CL200 Split Seam Compression Limiter. The larger inner diameter (ID) also accommodates the protective coating of ArmorGalv®, a zinc alloy thermal diffusion coating that provides up to 1000+ hours of salt spray protection for highly corrosive applications such as marine, automotive, mining and industrial manufacturing. The benefits of ArmorGalv® include no insignificant surfaces on the Limiter and that the entire ID receives full coating and protection.

Here is a link to the new CL220 Split Seam – Extra Clearance Compression Limiter specifications.

SPIROL offers a variety of formed and machined Compression Limiters to accommodate different compressive loads, positional tolerances and installation methods. Standard formed Compression Limiters include: Series CL200 Split Seam, CL220 Split Seam – Extra Clearance, CL350 Split Seam – Heavy Wall, CL400 Split Seam - Oval, CL460 Molded-In - Oval and the Series CL500 Molded-In designs. Standard machined options include: CL600 Aluminum and CL601 Headed Aluminum Compression Limiters, and the CL800 Brass and CL801 Headed Brass Compression Limiters.

*Author: Christie L. Jones | Director of Marketing, Vice President | SPIROL International Corporation

You may be interested in:

coiled spring pins

compression limiters

spirol

split seam

spring pins