The Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM in Dresden has succeeded in using Selective Electron Beam Melting (SEBM) to produce copper components that have not previously been shown using this process.

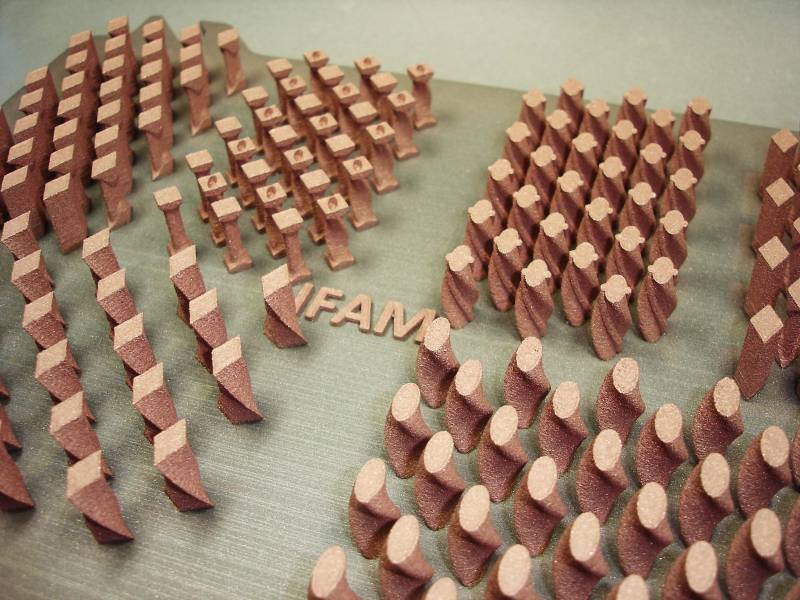

The technology demonstrator "Flow-Field XXL" impressively shows the hybrid production with pure copper via SEBM on stainless steel. A total of almost 200 pins with a height of 20 mm were manufactured in nine different designs. The construction volume of approx. 150 cm³ was generated in 18 hours on the Arcam Q20+ facility. In addition to the variety of structural examples, such as those used in heat exchangers, the large-area realization of the multi-material demonstrator is also impressive.

Manufactured by means of SEBM, completely dense structures are created, which, thus, achieve the necessary conductivities for the application as heat exchangers. In order to make the design details clearly visible, the pins were manufactured with thicknesses of 6 - 12 mm. Technologically, however, much smaller structures with thicknesses of up to 600 µm are possible, which significantly extend the potential application spectrum of the copper structures.

Author: Dr. rer. nat. Burghardt Klöden (Group Manager Additive Manufacturing - Electron Beam Melting)

You may be interested in:

copper

manufacturing

sebm

selective electron beam melting

stainless steel